Enlarge Image Fig.2 Method for preparing PBO nanofibers

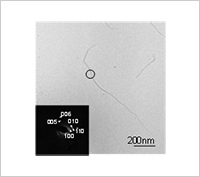

Enlarge Image Fig.3 TEM image of PBO nanofibers and an electron diffraction image of the circled area (lower left)

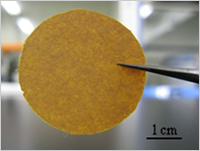

Enlarge Image Fig. 3 Photo of the PBO nanofiber mat

Enlarge Image

Preparation of rigid polymer nanofibers by new crystallization method

Tetsuya Uchida

Graduate School of Natural Science and Technology

Okayama University

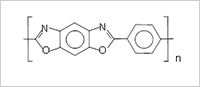

Poly(p-phenylene benzobisoxazole) (PBO) (Fig. 1) is a rigid polymer in which the molecular chains are unable to fold. PBO fibers have excellent physical properties, including high strength, a high elastic modulus, and high thermal stability.

However, nanofibers with diameters of less than 100 nm and aspect ratios higher than 100 have attracted attention recently because of potential applications in many areas, including high efficiency filters, organic electronics, electromagnetic shield materials, compact batteries, and high-performance polymer composite. Methods for the preparation of nanofibers include conjugated melt spinning, melt-blowing, and electro spinning, with the lattermost being the most versatile.

However, these methods require not only specialized equipment but also high voltages. Furthermore, using conventional nanofiber preparation methods for a rigid polymer such as PBO is difficult because it is insoluble in organic solvents, and soluble only in concentrated sulfuric acid and other similar acids.

We previously reported that single crystals with different forms can be produced by crystallizing PBO from dilute solutions in concentrated sulfuric acid. Here, we have used this result to develop new method for preparing PBO nanofibers with an average diameter of approximately 50 nm (Fig.3; Table1) via crystallization from a dilute solution in sulfuric acid (Fig.2).

Table 1 Properties of the PBO nanofibers

| Diameter | 53 ± 22 nm |

| Length | 6.7 ± 1.1 µm |

| Specific surface area | 88.4 g/m2 |

Furthermore, we prepared a PBO nanofiber mat by a simple method using filtration and a vacuum heating press. The PBO nanofiber mat (Fig.3) exhibited excellent mechanical properties such as high thermal stability and high porosity. Notably, the thermal diffusivity was anisotropic, with the magnitude in the in-plane direction of the film greater than that in the thickness direction (Table 2).

Table 2 Physical Properties of the PBO nanofiber mat

| Physical property | |

| Density | 1.10 ± 0.07 g/cm3 |

| Porosity | 28.7% ± 4.2 % |

| Elastic modulus | 1.48 ± 0.14 GPa |

| Thermal resistance: | |

| 5% weight loss | 610 °C |

| 10% weight loss | 650 °C |

| Specific surface area | 42.6 g/m2 |

| Thermal diffusivity: In-plane direction |

5.36 ± 0.38×10-6 m2/s |

| Thickness direction | 0.29 ± 0.04×10−6 m2/s |

Applications

PBO nanofibers: High performance nano-filler for polymer composite (high thermal stability, high thermal conductivity, electrically non-conductive, high elastic modulus, high strength)

PBO nanofiber mats: highly thermally stabile nanofiber filter, highly thermally conductive nanofiber sheet.

★Contact: Mototaka Senda, Ph.D.,

US & EU Representative of Intellectual Property Office,

Okayama University, 2450 Peralta Blvd. #119, Fremont,

CA 94536, USA

Email: takasenda@okayama-u.ac.jp